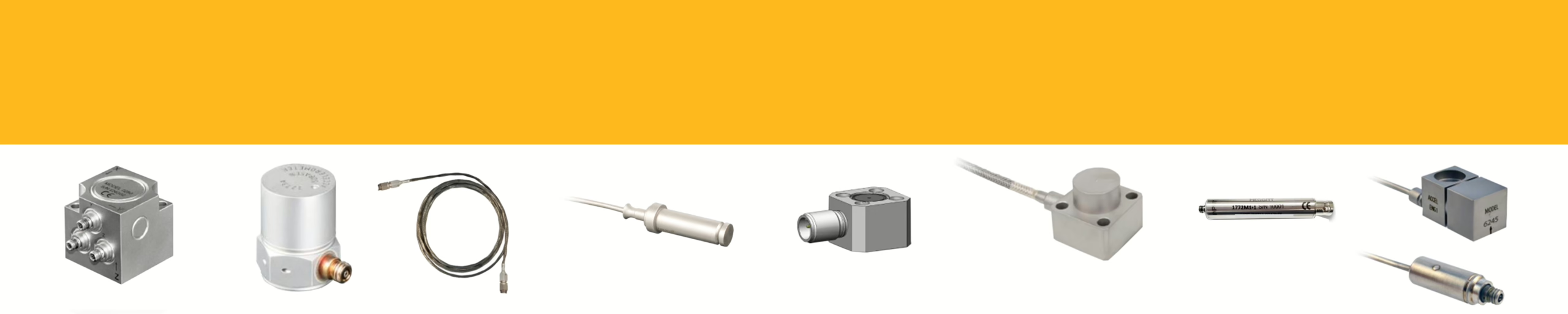

Accelerometers | Vibration Sensors

Accelerometers measure the levels of vibration in an engine or systems. They detect faults and prevent potential damage. They enable you to achieve the reliability and accuracy you need for your engine, aircraft, helicopter, UAS, space or transportation application.

From helicopter HUMS, to modern turbofans, our wide range of accelerometers are the core of all vibration and engine monitoring systems.

We provide a comprehensive range of accelerometers. Let our experts help you select the best device.

Aerospace Accelerometers

The vast majority of current transport aircraft rely on our accelerometers to monitor the condition and health of their engines.

They allow engine manufacturers to fine tune engine for increased efficiency and enable operators to optimize their maintenance.

The vibration data is fed into the Engine Monitoring Unit (EMU) which performs advanced trending, monitoring and prognostic functions.

These accelerometers can operate in extreme temperatures, up to 1500˚F (815˚C).

Our Piezo-electric accelerometers are ideally suited to a wide range of jet engine (civil and military) helicopter and test labs.

Dynamic Pressure Sensors

Dynamic Pressure sensors measure combustion instability in gas turbine combustion chambers. They can detect impending compressor surge or stall and monitor the combustion process. This enables operator to get more power using less gas, and to control emissions.

Extreme High Temperatures Vibration Accelerometers and Cables

High Temperature Piezoelectric (HTPE) Accelerometers and Extreme High Temperature Piezoelectric (EHTPE) Accelerometers for shock and vibration measurement of structures in industrial or laboratory applications involving high temperature, Gamma and Neutron radiation and loose-parts- monitoring systems.

Contact: Danny Roque

Business Development Manager

email: danny.roque@parker.com

+1 949.465.7700